X Ray

X-ray inspection systems locate all contaminants due to their density, chemical composition and mechanical dimensions.

For example metal, glass, ceramic and stone contaminants in food.

It also detects some plastics (PVC, rubber) as well as other product defects (cracks, trapped air).

Desired metals (for example: aluminum staples in sausage packages) can be hidden.

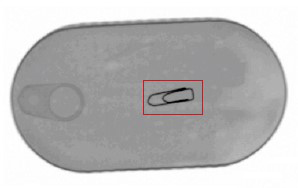

Clip in metal can

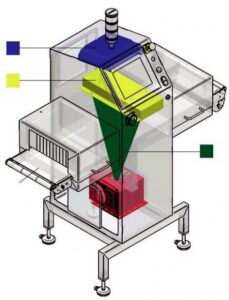

- Hinged lids can be attached – this saves considerable time on cleaning

- High performance X-ray tubes. High voltage power supply: Does not use water cooling, only use air conditioner as heatsink

- High resolution detection unit, for example: stainless steel contaminants can be detected from a size of 0.6 mm (in sphere)

- Compact, low center of gravity design that requires minimal space

- Excellent radiation protection. Higher than legal X-ray regulations (<1mSv / a)

- Easy to clean and maintain

- Flexible combination with various reject systems and output contacts

- Allows the simultaneous transport of different products

- A set of parameters is saved for each product

- The system automatically detects each product that passes through the X-ray fan and uses the correct set of parameters

- Therefore a manual product change is no longer necessary

- Separate options can be activated for each product (ex: border filter, weight, count

Multi-line inspection of up to 4 product lines operating in parallel.

This function can be used to hide the metal staple of a product. Without such exit concealment, the sensitivity of the product would be greatly decreased because the metal staple has a high density.

The staple is shown in the X-ray image (green frame) but is hidden from image processing by the software. The system can also check each product for a staple.

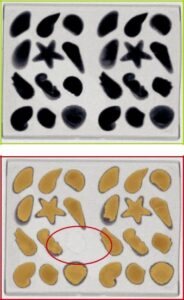

24 chocolates box

Checking the integrity of non-transparent containers using the counting function and verifying the position of the product.

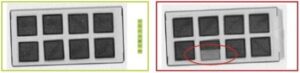

Weight control

Box of cookies

The innovative GRACIDA inspection system offers many advantages.

Using the operating system in real time with your flash card ensures:

- Your hard drives and external drives are not prone to errors

- Total processor performance is used only for product inspection.

- No UPS is needed for product protection

Additional features and benefits

- Ethernet connection for data transfer and remote maintenance

- USB port for saving images, product backup and software updates

- Multiple capacity for the connection of photocells, rejection and separation system, etc. allowing versatile integration into the production line

- Remote maintenance through remote access

- Memory with capacity for up to 50 products